Navigating the Process of Engine Choice: Secret Factors to Take Into Account

The procedure of engine option is a complex venture that demands cautious assessment of numerous vital variables to ensure positioning with operational objectives. Performance demands, gas effectiveness, and monetary restrictions are simply the beginning; considerations around ecological impact and maintenance assistance play an essential duty in the decision-making structure. Understanding how each of these elements connects can substantially influence the efficiency and durability of your financial investment. The ins and outs of each aspect may not be immediately apparent, motivating further assessment of how to purposefully browse this complicated landscape.

Efficiency Demands

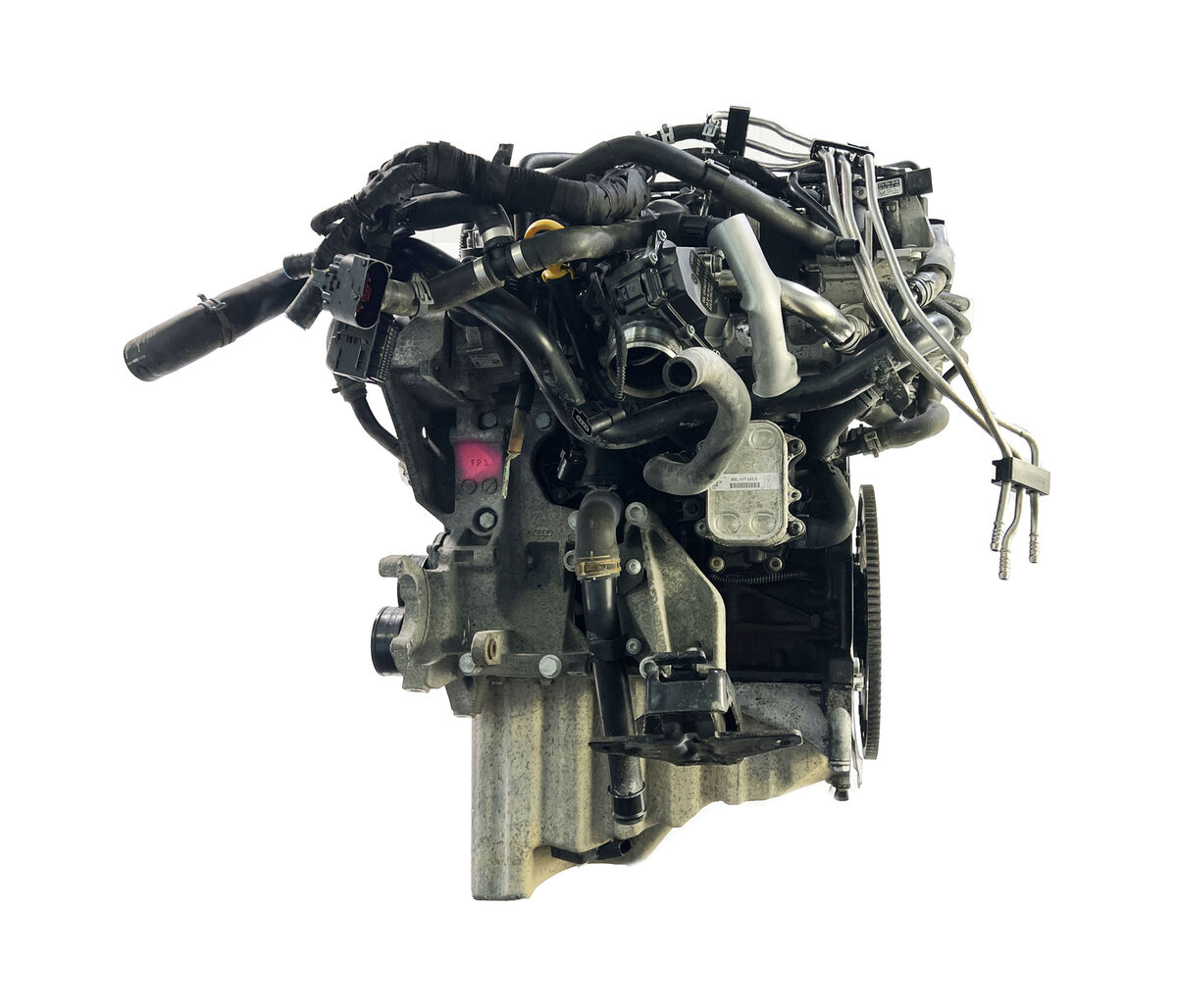

When selecting an engine, it is crucial to establish clear efficiency requirements that straighten with the intended application. Efficiency demands encompass a variety of aspects, consisting of power output, torque characteristics, and responsiveness, which need to be tailored to the particular demands of the vehicle or machinery in inquiry.

Power result, usually measured in horse power, identifies the engine's capability to propel an automobile or do a task successfully. Torque, on the various other hand, is necessary for applications requiring strong preliminary velocity or heavy lifting capacities. An understanding of the operational atmosphere is also essential; for example, engines designed for off-road applications might need various efficiency characteristics contrasted to those intended for highway usage.

In addition, take into consideration the operational load and duty cycle, as these aspects influence the engine's longevity and integrity. In high-load scenarios, a robust engine design may be needed to stop premature wear or failure.

Gas Performance Factors To Consider

While performance needs are critical, gas effectiveness is similarly crucial in the engine option procedure, as it straight affects operating expense and environmental sustainability. Fuel-efficient engines take in much less fuel each of job carried out, which not only lowers total expenditure however additionally lessens greenhouse gas discharges. As organizations progressively prioritize sustainability, picking an engine that maximizes gas effectiveness can improve corporate responsibility and compliance with environmental laws.

When reviewing fuel performance, it is vital to consider the engine's layout and innovation - amarok engine for sale. Technologies such as turbocharging, direct gas injection, and crossbreed systems can considerably boost gas economy. Additionally, recognizing the operating problems and responsibility cycles of the engine application is vital; engines might execute in different ways under differing tons and speeds

Furthermore, suppliers usually supply fuel intake data that can be used to compare numerous engine alternatives. It is suggested to assess these specifications in real-world scenarios to ensure accuracy. Finally, the sort of gas used can likewise affect gas effectiveness; alternative gas may provide much better performance and lower emissions. In summary, fuel performance is a multi-faceted consideration that calls for extensive assessment during the engine option procedure.

Budget and Price Evaluation

Budget and cost analysis works as a vital part in the engine option procedure, affecting both short-term financial investments and long-lasting functional expenditures. When evaluating potential engines, it is important to think about not just the preliminary acquisition cost however also the overall cost of possession, which incorporates installation, upkeep, gas consumption, and potential downtime.

A detailed analysis must begin with the upfront costs related to the engine, including needed alterations or ancillary tools. Focusing entirely More Bonuses on initial expenses might lead to illinformed decisions. Assessing operating prices over the engine's lifespan is equally important, as extra costly engines may provide exceptional gas effectiveness or decreased upkeep requirements, inevitably resulting in cost savings.

Environmental Influence Elements

Recognizing ecological impact aspects is essential in the engine selection process, as sustainability considerations have ended up being increasingly vital for both governing compliance and company responsibility. Organizations needs to review the emissions produced by numerous engine kinds, including carbon dioxide, nitrogen oxides, particle matter, and unburned hydrocarbons. These emissions add substantially to air contamination and environment change, necessitating a cautious evaluation of the engine's eco-friendly footprint.

In addition, fuel type plays an essential role in environmental influence. Engines powered by sustainable power sources, such as biofuels or hydrogen, have a tendency to have a lower ecological influence contrasted to standard nonrenewable fuel sources. Additionally, the lifecycle analysis of the engine, from manufacturing through procedure to disposal, should be taken into consideration to understand the full range of its environmental implications.

Maintenance and Support Alternatives

When choosing an engine, the schedule of upkeep and assistance choices is a critical factor to consider that can considerably affect functional effectiveness and long life. Comprehensive upkeep plans ensure that the engine operates at peak efficiency and minimizes unexpected downtimes. It is important to examine the supplier's assistance network, including the availability of qualified technicians and solution centers.

Assessing the access of extra components is also vital. A reputable supply chain for parts can lower lead times for repair services and upkeep, thereby boosting general performance. Furthermore, consider the simplicity of getting technological documentation and training resources, which are important for ensuring that workers are well-appointed to deal with regular and emergency situation situations.

One more essential element is the guarantee and service agreements used by the producer. These arrangements can provide assurance and economic defense versus unforeseen issues. Ultimately, a proactive strategy to maintenance and support not just expands the life of the engine yet likewise contributes to the general success of the procedure. Mindful factor to consider of these facets will certainly result in educated decisions that straighten with operational goals and spending plans.

Verdict

In verdict, the procedure of engine selection necessitates an extensive analysis of different important aspects, consisting of efficiency requirements, gas effectiveness, budget plan constraints, environmental impact, and maintenance support. By meticulously analyzing these elements, educated decisions can be made that align with functional goals and sustainability objectives. Inevitably, a critical method to engine choice click here to find out more will certainly guarantee optimum efficiency and durability while resolving economic and environmental considerations efficiently.

While efficiency demands are crucial, gas efficiency is equally crucial in the engine option procedure, as it directly impacts operating expenses and ecological sustainability. As organizations increasingly focus on sustainability, picking an engine that optimizes fuel efficiency can enhance business duty and compliance with ecological guidelines.

Additionally, recognizing the operating conditions and duty cycles of the engine application is essential; engines might execute differently under varying loads and rates. (amarok engine for sale)

Reviewing operating expenses over the engine's life-span is similarly crucial, as a lot more expensive engines may offer premium fuel performance or reduced upkeep demands, eventually leading to cost financial savings.

In verdict, the process of engine choice demands a thorough evaluation of different crucial factors, including performance demands, gas effectiveness, budget plan restrictions, environmental impact, and upkeep support. - amarok engine for sale